|

The

ELTROPULS process is completely reproducible.

Process

parameters are microprocessor controlled

and optimised throughout the heat treatment

cycle, to produce the best metallurgical

results. Parts can be heated in the shortest

possible time, in vacuum, by radiation or

in an inert atmosphere, with natural or

forced convection. Even the most complicated

programs can be easily reproduced.

After

reaching the end of the heat and soak steps,

the part can be automatically cooled.

The

cooling method can be selected to meet the

requirements of the part - slowly, in a

vacuum to insure freedom from distortion,

or more quickly, in an inert atmosphere

with natural or forced convection, for high

throughput and productivity.

Passivated

surfaces can be activated by sputter cleaning.

Critical

chemical reaction kinetics are improved

by sputtering.

The

ELTROPULS plasma power is automatically

limited to just the amount necessary

This

ensures uniform temperature of the

parts and allowing loading of a maximum

number of parts in the furnace. Using the

smallest amount of power for the process

prevents overheating of thin sections (as

occurs with technologies lacking pulse duration

and duty-cycle control). This guarantees

consistent nitrided layers whether full

loads or partial loads are run.

Load

size is not critical.

Parts

with different geometries can be treated

at the same time. Cold-Start to Cold-Stop

processing permits small batch operations

without utility cost penalties.

The

low consumption of electrical power, process

gases and cooling water

ensures

a beneficial surface modification operation

at minimum expense.

All

of these features permit high parts production

with the best metallurgical quality.

The

surface treatment process with pulsed plasma

offers unique advantages: The

surface treatment process with pulsed plasma

offers unique advantages:

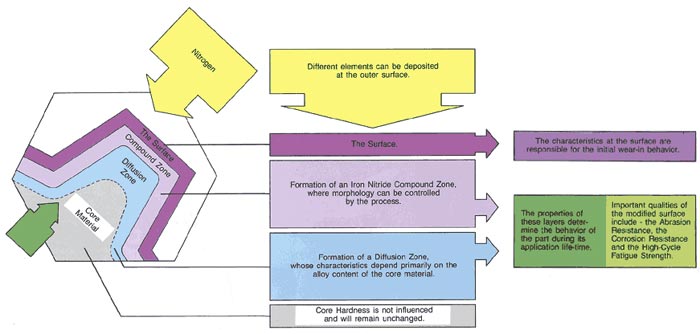

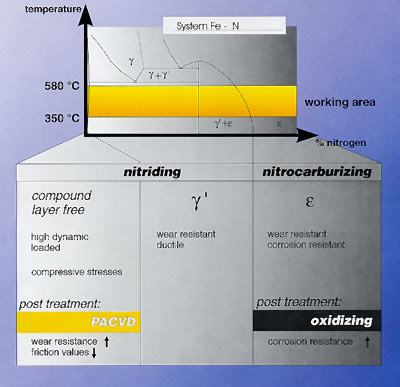

- With the ELTROPULS

process all possible nitrided layers can

be created.

- The ductile g' layers are normally 2 to 8 mm

thick and the e layers, which also have good corrosion resistance,

have a thickness of up to 20 mm. Both layer types display good wear resistance.

- Optimal layer thickness and type can be tailored to meet specific application

requirements by the ELTROPULS process.

- For dynamic highly loaded parts or tools, a think g'

layer or compound-free layer with high

compressive stresses is recommended.

- The properties of nitrided

layers can be further improved with post

treatments.

- Post oxidation gives

the parts a decorative appearance and

improves the corrosion resistance.

- Hard coating enhances

hardness and wear resistance and reduces

friction.

- The ELTROPULS-process

can produce all of the mentioned layers

at low cost with precise repeatability.

- Optimal shape control

is guaranteed to prevent postnitriding

machining.

|